categorieS

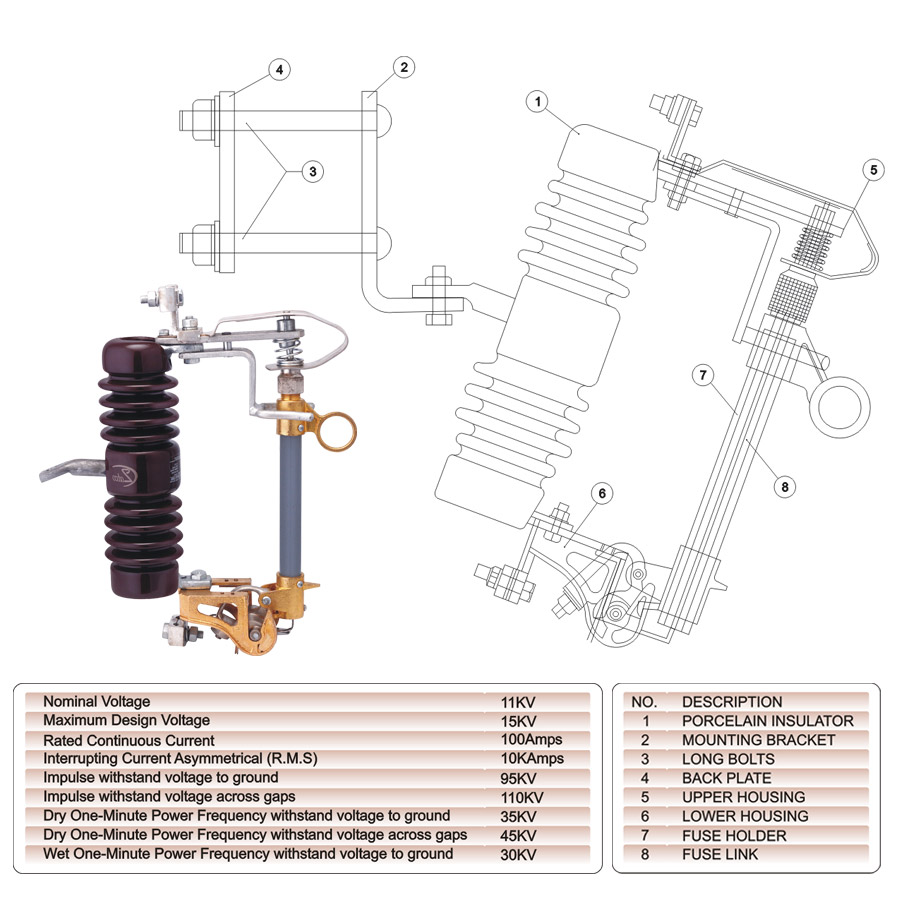

FUSE CUTOUT 11 KV

11KV Drop Cut Fuse Cut Outs are widely used for protection / isolation of distribution transformers, This specification not only stipulates the electrical and mechanical requirements of good quality drop out fuse cut outs but also specifies important constructional features to ensure uniformity and proper quality.